Whether you already handle oxidising products or are simply interested in learning more about the necessary safety precautions, this blog post will provide you with valuable insights to protect yourself and others from potential hazards.

What does the flame over circle pictogram mean?

The flame over circle CLP pictogram, referred to as the oxidising symbol, is a potent indicator that the substance in question is an oxidiser. Delving into the world of oxidisers is crucial, as they possess the capacity to ignite or intensify fires, and in the case of strong oxidising substances, even trigger explosions.

What are oxidisers?

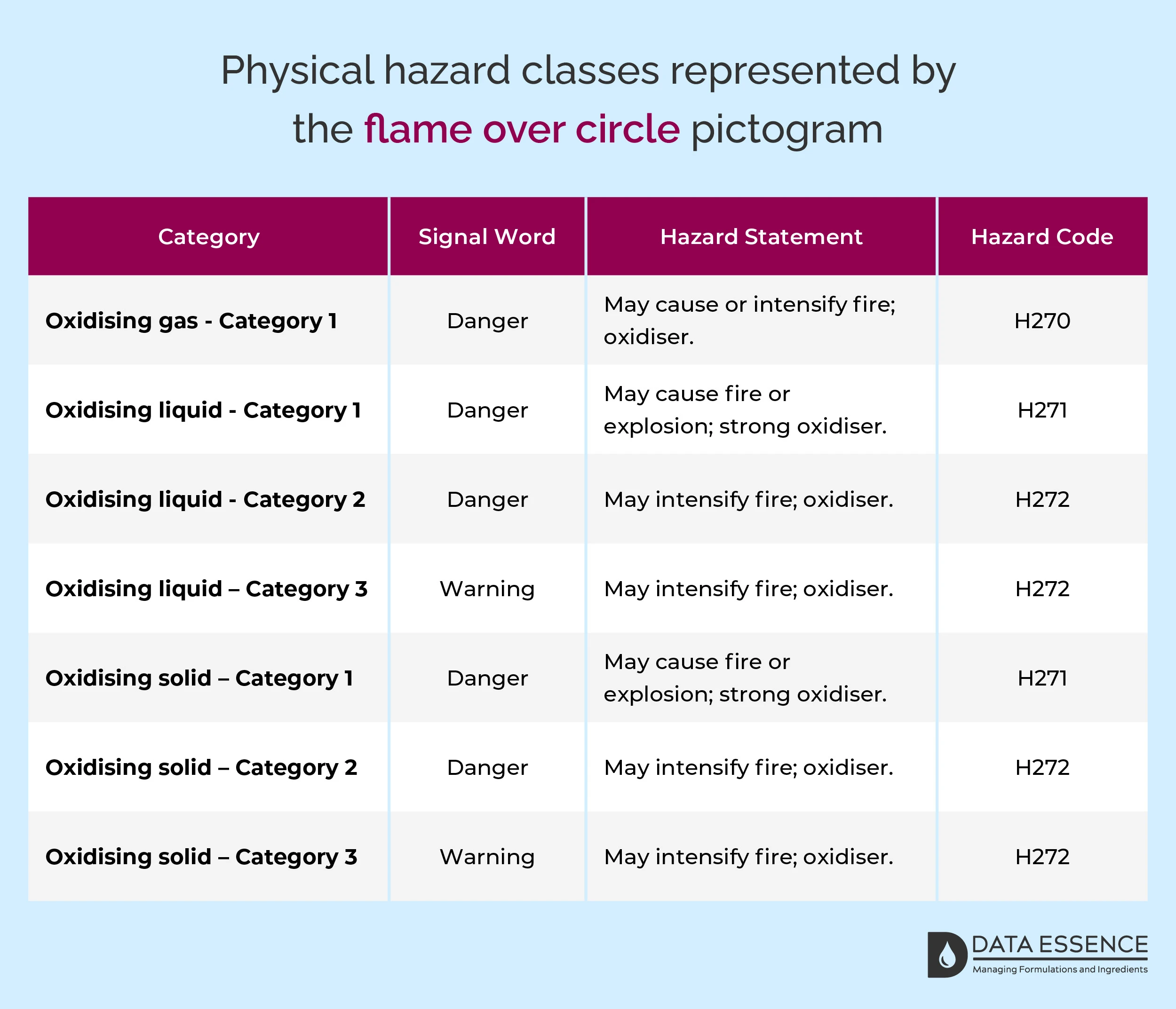

Hazard classes represented by the flame over circle pictogram

The three hazard classes represented are oxidising gases, oxidising liquids and oxidising solids. We will look at each of these hazard classes in turn in relation to signal words, hazard statements and hazard codes.

The implications of oxidisers

Fires typically require fuel, oxygen, and an ignition source. In most cases, air provides the necessary oxygen (which is around 21% in air). Oxidising solids, liquids, or gases release oxygen or other oxidising substances (like bromine, chlorine, or fluorine), making them a significant fire hazard. While oxidisers do not burn themselves, they can:

- Accelerate fire development, making it more intense and hotter than usual.

- Cause non-combustible materials to burn rapidly.

- Induce some flammable materials to ignite spontaneously, even without a visible ignition source like a spark or flame.

Always consult the Safety Data Sheet (SDS) and product CLP label to thoroughly understand the risks associated with the specific product you are working with. When in doubt, seek clarification and ask questions to ensure safety.

Protective measures for oxidisers

When handling materials that display the flame over circle, it is imperative to adopt rigorous safety measures. These include ensuring that these substances are stored away from any potential ignition sources—think heat, sparks, open flames, and hot surfaces. Smoking should be prohibited in proximity to these hazardous materials.

Equally important is the use of personal protective equipment (PPE). This typically includes protective gloves, specialised clothing, as well as eye and face protection. These precautions form a robust barrier between you and the potential hazards.

In the unfortunate event of accidental contact with these substances, swift action is vital. Immediately rinse contaminated clothing and skin with copious amounts of water before removing the affected attire. This rapid response can help minimise the risks associated with oxidising materials.

To safely handle products marked with the flame over circle pictogram:

- Consult the SDS: Always review the Safety Data Sheet (SDS) for comprehensive hazard information and precautions.

- Consider alternatives: If possible, substitute with less hazardous products in your workplace.

- Avoid ignition sources: Keep liquids and solids away from heat, flames, and combustibles. Maintain gas valves and fittings free from oil and grease.

- Ventilation: Use these products in well-ventilated areas and wear appropriate protective gear as required.

- Personal protective equipment (PPE): Ensure workers are well-trained in its selection, use, and maintenance.

- Waste management: Remove combustible waste promptly.

- Incompatible materials: Keep away from incompatible materials like greases, lubricants, solvents, paints, or thinners.

- Caution with oxidisers: Be cautious when mixing oxidisers with water and follow supplier instructions.

- Container handling: Do not return unused product to its original container. Keep containers tightly closed unless instructed otherwise. Check vent caps if applicable.

- Spill response: Prevent spills and report promptly. Exit the area in case of a spill or leak.

- Maintain cleanliness: Keep work areas clean to prevent contact with hazardous materials.

- Hygiene: Refrain from smoking, eating, or drinking at work. Wash hands thoroughly after handling.

- Inform maintenance personnel: Alert maintenance staff about product hazards and necessary precautions before work commences.

Safe storage for oxidisers

- Follow the SDS instructions: Adhere to any storage instructions on the Safety Data Sheet (SDS), including quantity and temperature limits.

- Use recommended containers: Store the product in containers recommended by the supplier, typically the ones in which it was originally shipped.

- Avoid incompatibles: Keep the product away from materials listed as incompatible on the SDS.

- Ventilation: Ensure well-ventilated storage for gases.

- Separate oxidisers: Store oxidising liquids or solids separately.

- Control environment: Choose a cool, dry location away from direct sunlight and exit routes. Display warning signs and keep ignition sources like heat, sparks, or open flames away. Prohibit smoking nearby.

- Limit quantities: If possible, avoid storing large quantities.

- Regular inspection: Routinely check the storage area and containers for leaks or damage. Use compatible trays to contain spills or leaks.

- Empty container handling: Empty containers may hold hazardous residues; store them separately and keep them closed.

- Non-combustible infrastructure: Do not use wooden or combustible pallets for storing oxidizing products. Storage areas should have non-combustible walls, floors, shelving, and fittings.

- Emergency equipment: Ensure fire-fighting and spill clean-up equipment is readily accessible.

- Compliance: Adhere to all relevant health and safety regulations, as well as fire and building codes.

Conclusion

By acknowledging the potential risks associated with oxidisers, such as igniting or intensifying fires, and implementing appropriate safety measures, we create a safer working environment for employees and minimise the possibility of accidents. Storing, transporting, and handling these products in accordance with the flame over circle pictogram guidelines is essential to protect not only employees but also customers and the environment.