Manage your compliance and business needs for the Flavour, Fragrance and Essential Oil Industries

dataEssence is providing your business with the operational tools and management information necessary to satisfy your clients’ needs in the most productive and profitable way.

Choose a solution to suit your needs

CLP & SDS Service

If you do not need a comprehensive software installation yet, but still need a more efficient and cost-effective CLP & SDS solution, we can help!

from

£250 + VAT

(if applicable)

dataEssence Core

The ‘Core’ software package allows a business to manage ingredients, formulations,

and regulatory documents

and labels.

from

£2,995 + VAT

(if applicable)

*Monthly payment plans available

CLP & SDS Service

If you do not have a need for a dataEssence software solution but still need a more efficient and cost-effective Safety Data sheet solution, we can help!

Using our SDS and CLP Authoring service we can provide bespoke Safety Data Sheets & CLP label information for any blends of Fragrance and Essential oils and other flavour and fragrance ingredient mixtures for you using our dataEssence software.

We will put the details of the ingredients you are using to create your unique blend into the dataEssence system, it will calculate all the regulations, and we will send you the following required regulatory documentation:

- Safety Data Sheet which includes an IFRA Conformity Certificate

- Allergen Analysis

- CLP label information

dataEssence Core

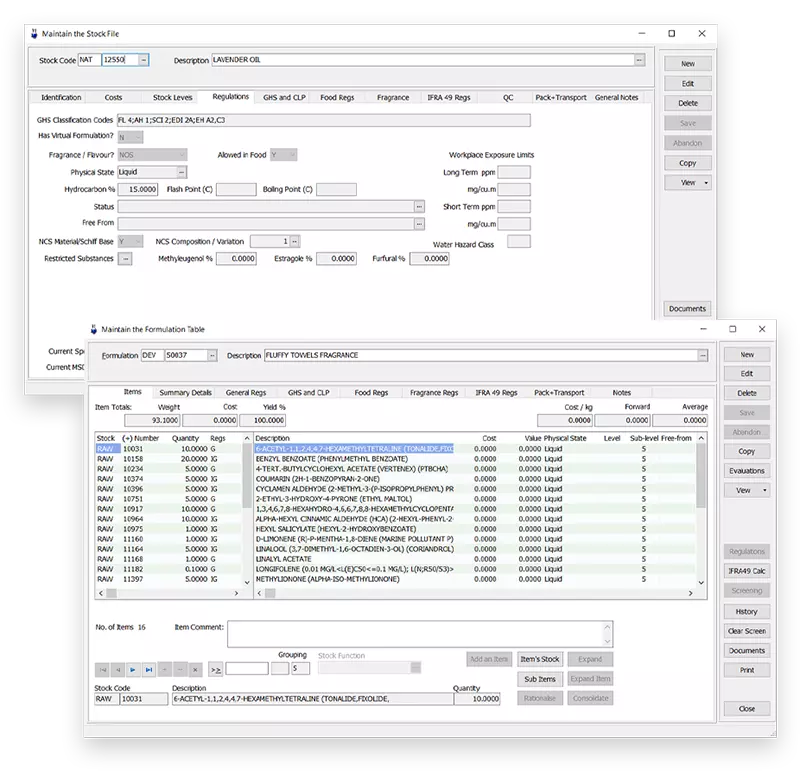

dataEssence ‘Core’ allows a business to manage ingredients, develop and maintain formulations, and to create regulatory documents and labels.

- Stock Maintenance

- Formulation Management

- Regulation Management

The powerful formula development systems will enable you to keep thousands of formulas in an easy to search system with lots of user-friendly tools to help you manage your raw materials, ingredient lists and complex formulations.

This software simplifies the complex regulatory processes with automated and accurate calculation of key regulatory issue so that users can easily create Safety Data Sheets, IFRA conformity certificates, Allergen analysis, Ingredient declarations and GHS/CLP labels for any raw ingredient or formula.

The calculations are constantly being extended but currently cover GHS and CLP, REACH, IFRA, FEMA, Food Regulations, Status (e.g. organic, kosher, halal and natural) and Free From.

Are you tired of slow production of appropriate labels & docs?

Book a demo to see how dataEssence can help you save time &

energy so you can focus on other aspects of your business!

dataEssence Enterprise

dataEssence is a modular system and as such is fully scalable, giving you the flexibility to buy as many of the modules (and user licences) as your business requires and increase this as the needs of your business grow. A range of additional dataEssence software modules will enable managing your expanding needs for a complete solution from sales enquiry to invoice. It will allow managing R&D, stock, batches, manufacturing, sales, and purchase order processing.

Stock Take Module

The addition of the Stock Take module helps the work of the entire stock take process be more efficient.

Applications & Evaluations Module

Briefs & Submissions Module

Sales Orders Module

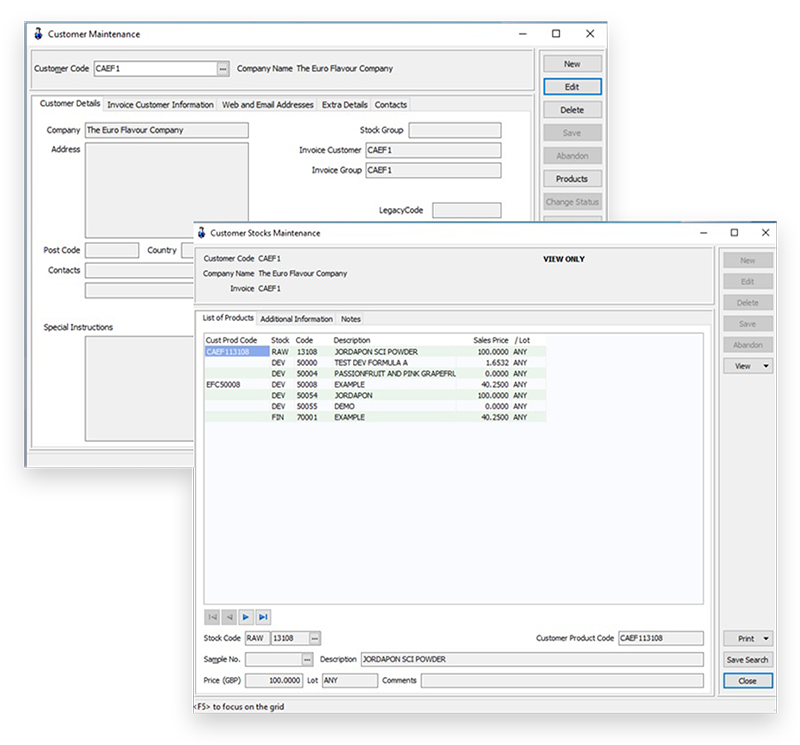

Customers & Products Module

Suppliers & Materials & Purchase Order Processing Module

Works Orders Module

Details of products, pricing and supplier information are held against each supplier within dataEssence thus allowing purchase orders to be raised. This allows not only individual pricing and coding details but also the recording of material approvals and the automatic production of the material specifications.

All purchase orders are based on an individual price list for each supplier with the ability to record the supplier’s own coding and descriptions. Multiple prices can be recorded for each product to reflect any special terms or quantity breaks. dataEssence can display all the potential suppliers and historic purchase orders to help in the choice of supplier for the next order.

dataEssence Documents

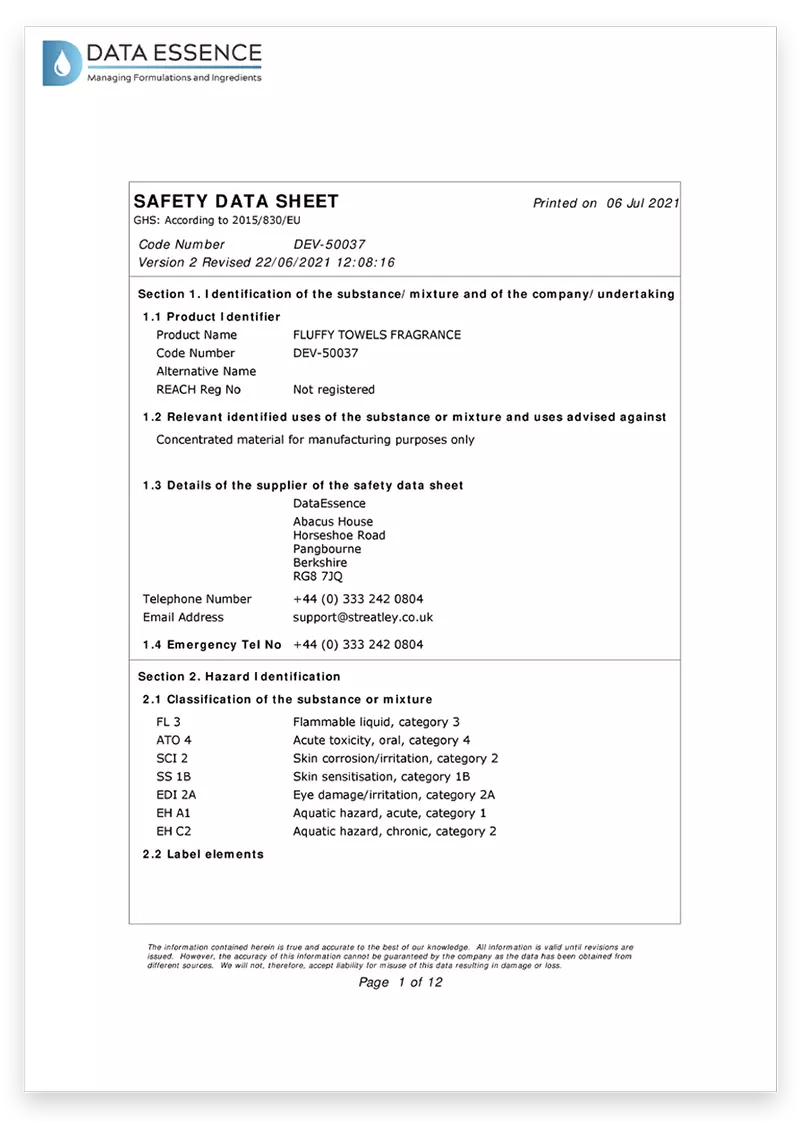

Safety Data Sheet (SDS)

Within the Safety Data Sheets, it includes sections for the IFRA Conformity Certificate, Allergen Analysis, Ingredient Declaration for label, Food Allergen Declaration, Vegetarian Declaration and GMO Declaration.

GHS/CLP label

An important part of chemical management is the clear provision of information about any dangerous properties that chemicals may have. dataEssence will allow you to print a GHS label and a CLP label for a Formulation or any raw material or ingredient.

IFRA Certificate

dataEssence supports the IFRA 49th & IFRA 50th Amendments allowing you to produce IFRA conformity certificates for your products that adhere to these regulations.

Subscribe to our newsletter

Join our mailing list and be the first to hear about our latest news and features.