Whether you already handle corrosive products or are simply interested in learning more about the necessary safety precautions, this blog post will provide you with valuable insights to protect yourself and others from potential hazards.

What does the corrosion pictogram mean?

What are corrosive substances?

These corrosive substances often have more than one danger. For example, potassium permanganate is not only corrosive but is also an oxidiser, irritant, and can harm human health. Similarly, potassium hydroxide corrodes metals like aluminium and zinc, and it can burn your skin and damage your eyes. Some corrosive substances are also flammable.

You could be exposed to corrosive substances by accidentally spilling them, getting them on your skin, or even breathing in the fumes. So, it is essential to be incredibly careful when handling these materials.

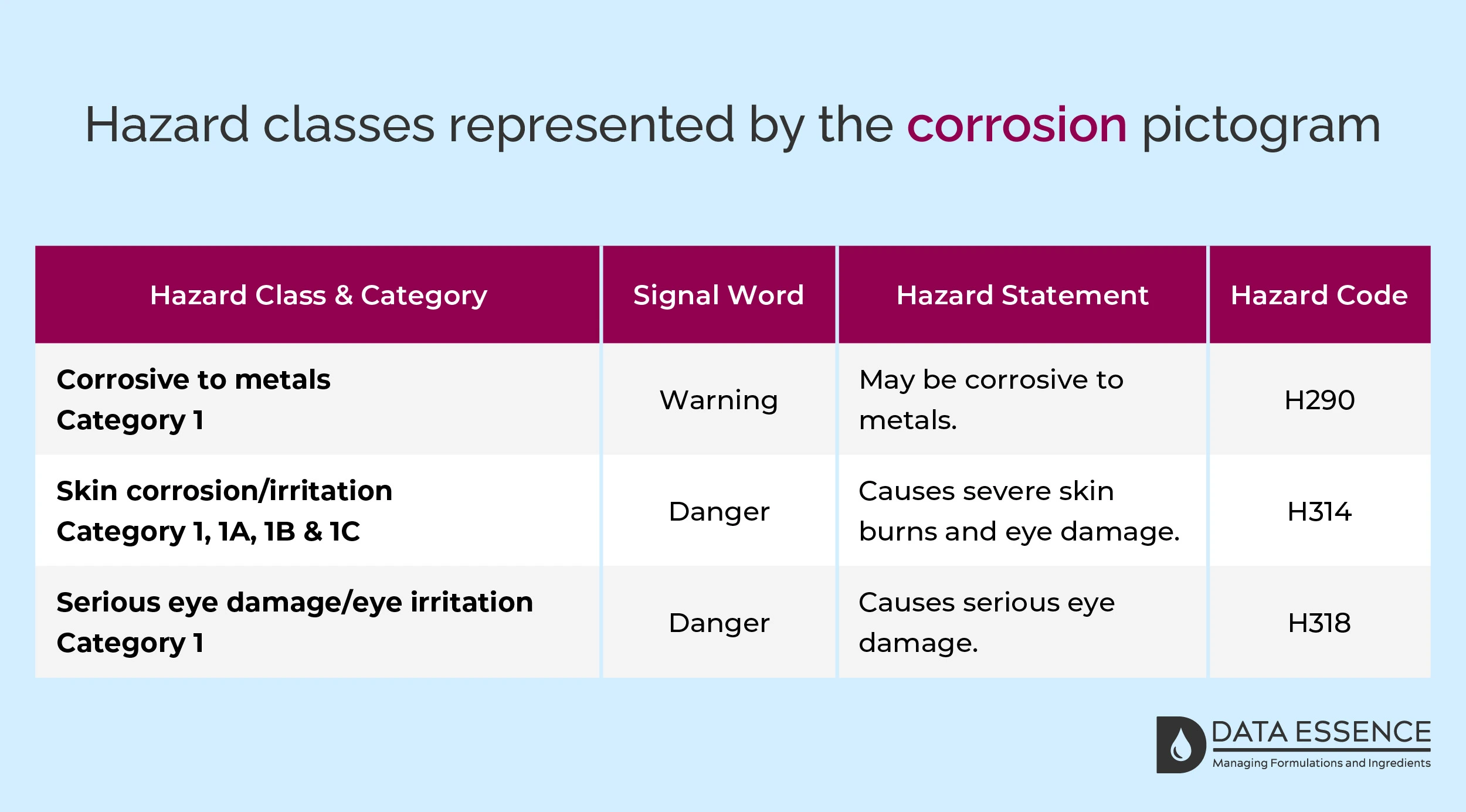

Physical hazard classes represented by the corrosion pictogram

One physical hazard class is represented, this being corrosive to metals, and the two health hazard classes represented are skin corrosion and serious eye damage. We will look at each of these hazard classes in turn in relation to signal words, hazard statements and hazard codes.

The implications of corrosive substances

Products with the corrosion pictogram may also have additional hazards, including health risks like toxicity, carcinogenicity, or reproductive toxicity, as well as physical hazards such as flammability or reactivity. Corrosive substances can react dangerously with other chemicals, potentially producing toxic or explosive byproducts. Refer to the Safety Data Sheet (SDS) for specific information regarding which materials the corrosive product can affect, such as metals, plastics, or wood, typically found in Section 10: Stability and Reactivity.

Always consult the Safety Data Sheet (SDS) and product CLP label to thoroughly understand the risks associated with the specific product you are working with. When in doubt, seek clarification and ask questions to ensure safety.

Protective measures for corrosive substances

To safely handle products marked with the corrosion pictogram, follow these steps:

- Review safety information: Always consult the Safety Data Sheet (SDS) to understand all the hazards and necessary precautions for the specific product. Seek clarification if needed. Follow the supplier’s recommendations for venting drums, if applicable.

- Consider substitutes: If possible, consider substituting the hazardous product with a less dangerous alternative.

- Retain original packaging: Keep the product in its original packaging.

- Prevent leaks: Inspect containers for any damage or leaks before handling.

- Prevent release: Prevent the release of dust, gas, mist, vapor, or spray into the workplace.

- Inhalation risk: Avoid breathing in dust or mist if they are generated during use. Use the product only in well-ventilated areas and use the smallest amount necessary.

- Eye and skin contact: Prevent skin contact and avoid getting the product in your eyes.

- Personal hygiene: Wash your hands and skin thoroughly after handling.

- Personal protective equipment: Wear appropriate protective gear, including respiratory protection, gloves, clothing, eye protection, and face protection as directed by your employer.

- Proper PPE training: If personal protective equipment is required, ensure workers are well-trained in its selection, use, and maintenance, referencing the SDS for guidance.

- Container handling: Dispense the product carefully and keep containers closed when not in use. Use corrosion-resistant equipment like pumps, scoops, or shovels.

- Mixing: Do not mix the corrosive product with water unless necessary and do so slowly by adding the corrosive to cold water in small amounts while stirring frequently.

- Safe transportation: Handle containers with caution, using appropriate equipment like drum cradles for large drums and safety bottle carriers for smaller containers.

- Safety awareness: Immediately report any leaks, spills, or equipment failures, such as problems with ventilation systems. In case of a spill or leak, leave the area promptly.

- Spills: Absorb spilled material to prevent damage and clean up spills promptly and safely using appropriate PPE.

- Empty containers: Do not reuse empty containers, as they may still contain hazardous corrosive residues.

Safe storage for corrosive substances

To safely store products labelled with the corrosion pictogram, follow these guidelines:

- Maintain safe storage: Regularly inspect containers and storage areas for any signs of leaks or damage.

- Container safety: Use containers that are corrosion-resistant and have a resistant inner liner. Ensure compatibility with materials specified by the manufacturer or supplier.

- Storage safety: Store containers at a convenient height for easy handling, preferably below eye level to reduce the risk of accidents.

- Limit quantity: Keep the quantity of stored product as small as possible.

- Follow supplier recommendations: Adhere to supplier recommendations regarding storage temperature limits, if applicable.

- Label and inventory: Implement a “first in, first out” policy and mark the date of container receipt and the date of first use.

- Leaks and spills: Use trays made of compatible materials to contain leaks or spills.

- Incompatible materials: Avoid storing corrosive materials near incompatible substances, and post warning signs as needed. Consult the SDS for specific information.

- Corrosion resistant storage: For larger quantities of corrosive products, utilise proper corrosive storage cabinets equipped with corrosion-resistant interiors and hardware. Do not use flammable storage cabinets, as they lack corrosion resistance.

- Safety: Ensure that firefighting and spill cleanup equipment is readily accessible.

- Empty containers: Store empty containers separately, as they may contain hazardous residue, and keep them closed.

- Regulatory compliance: Comply with all relevant health and safety regulations, as well as fire and building codes.

Conclusion

By acknowledging the potential risks associated with corrosive substances, such as the potential to corrode metals and inflict severe harm to both the skin and the eyes, and implementing appropriate safety measures, we create a safer working environment for employees and minimise the possibility of accidents. Storing, transporting, and handling these products in accordance with the corrosion pictogram guidelines is essential to protect not only employees but also customers and the environment.